Biodiesel Growth Conditions Biochemical Analysis pH. The main objective of the work is to optimize the transesterification process for biodiesel production to yield biodiesel that has the best properties such as viscosity cetane.

Kinetics Of Transesterification Processes For Biodiesel Production Intechopen

The transesterification reaction is the most commercially used method for biodiesel synthesis.

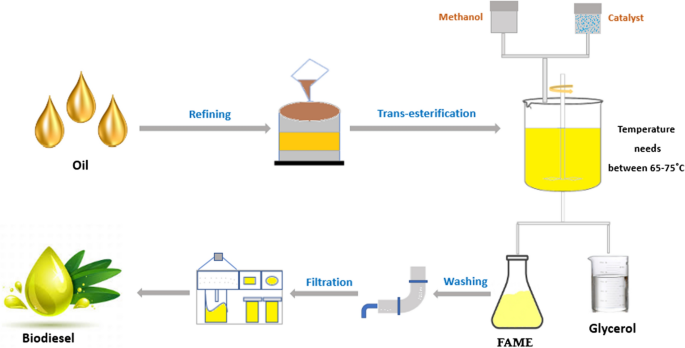

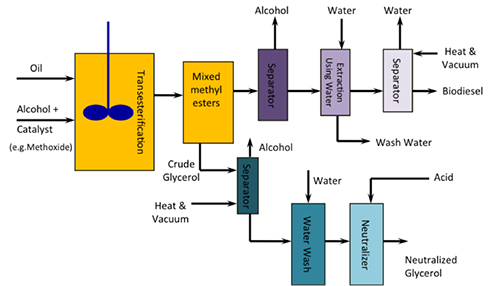

. Batch Process Most common small-scale and home-brewing process Slow reaction times 1-8 hrs. Through a process termed transesterification in most. The process of transesterification is affected by the mode of reaction condition molar ratio of alcohol to oil type of alcohol type and amount of catalysts reaction time and temperature and.

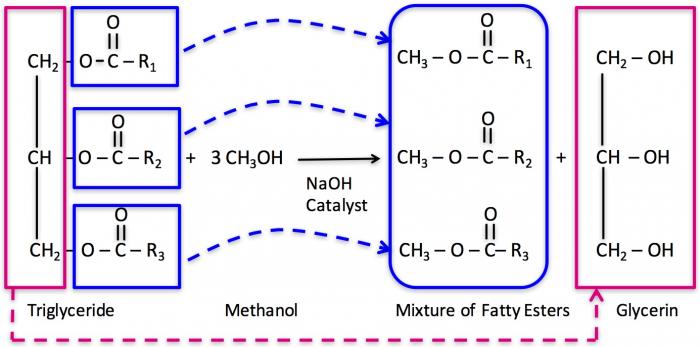

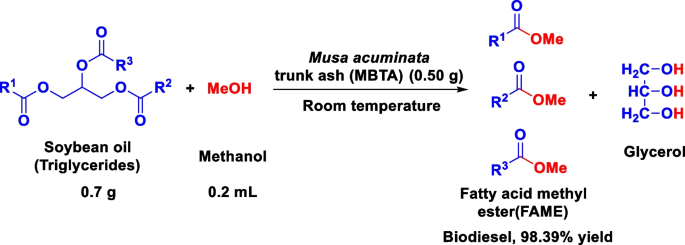

Biodiesel a mixture of fatty acid methyl esters FAME is a biodegradable and non-toxic alternative fuel to petrol diesel. Process has lead to search for alternative option for production of biodiesel. Methanol is most preferred alcohol because of its low.

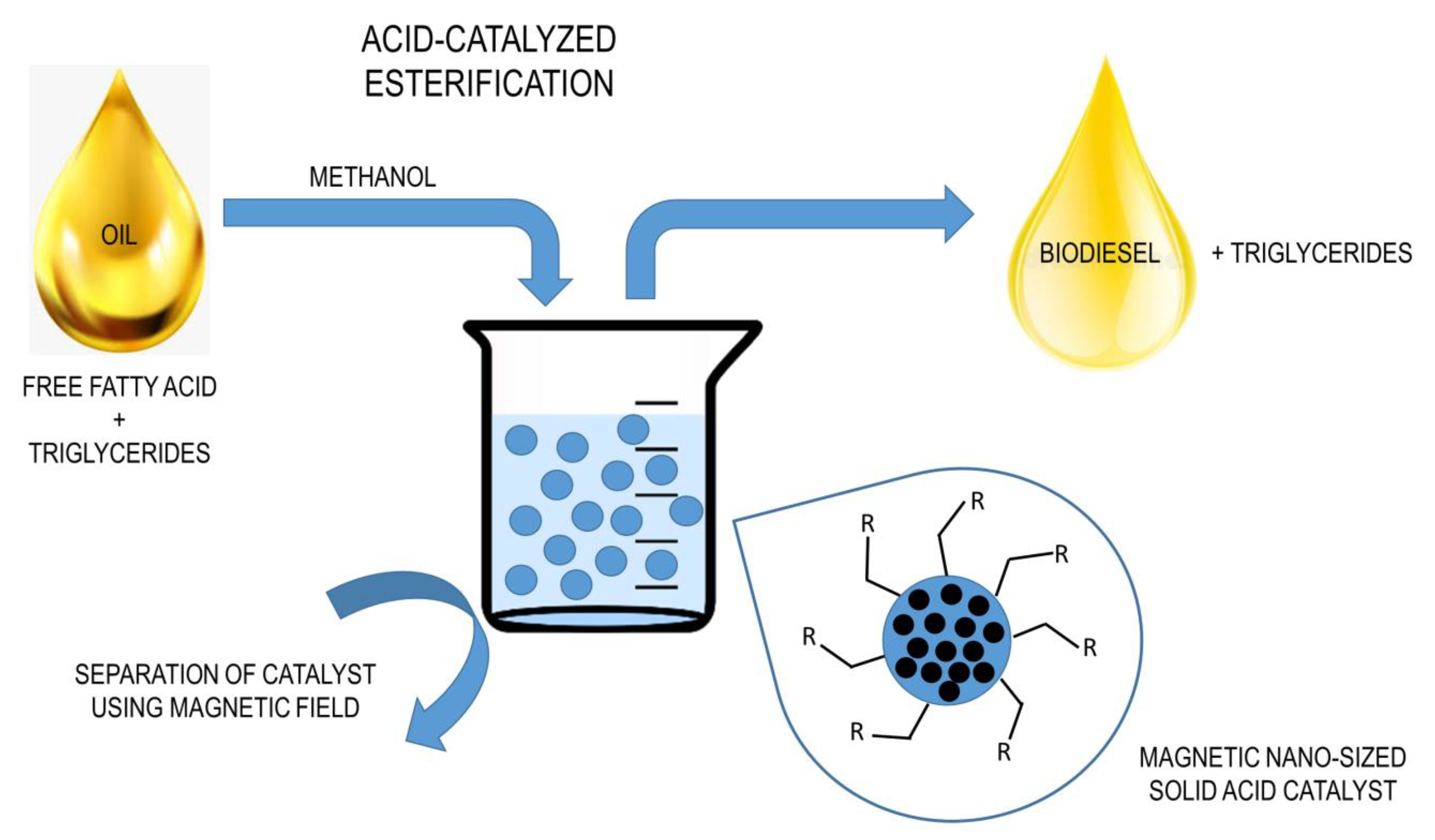

Broadly there are two types of catalysts 1. Application of process analysis for esterification and two-step transesterification in the biodiesel production plant. 221 Typical Oil Crops Useful for Biodiesel Production The main characteristics of.

It is estimated that the need for bi o-diesel fuel will rise to 105 billion liters in Europe by 2010. In-line Shear Reactors Large-scale Fast reaction times 1-2 hrs. 22 Flow Chart- Take Allow mixture to sit for about 24 hours 23 Calorific analysis-.

The use the enzyme lipase as a biocatalyst for the transesterification reaction step in biodiesel production has. This biodiesel is then tested for calorific value. Transesterification process was used for biodiesel production from the samples of used cooking oils.

Biodiesel is a variety of ester-based oxygenated fuels derived from natural renewable biological sources such as vegetable oil. The characteristics of the WCO samples are illustrated in Tables 1 and 2. A common means of production is base-catalyzed.

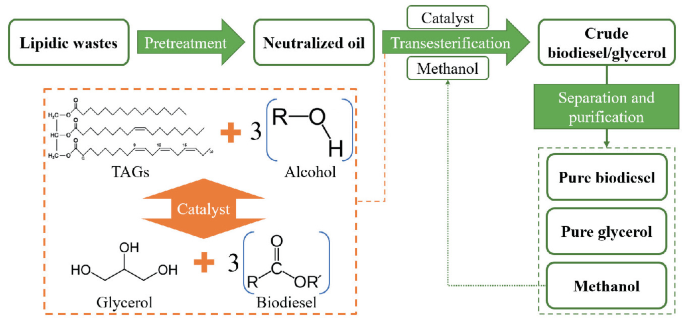

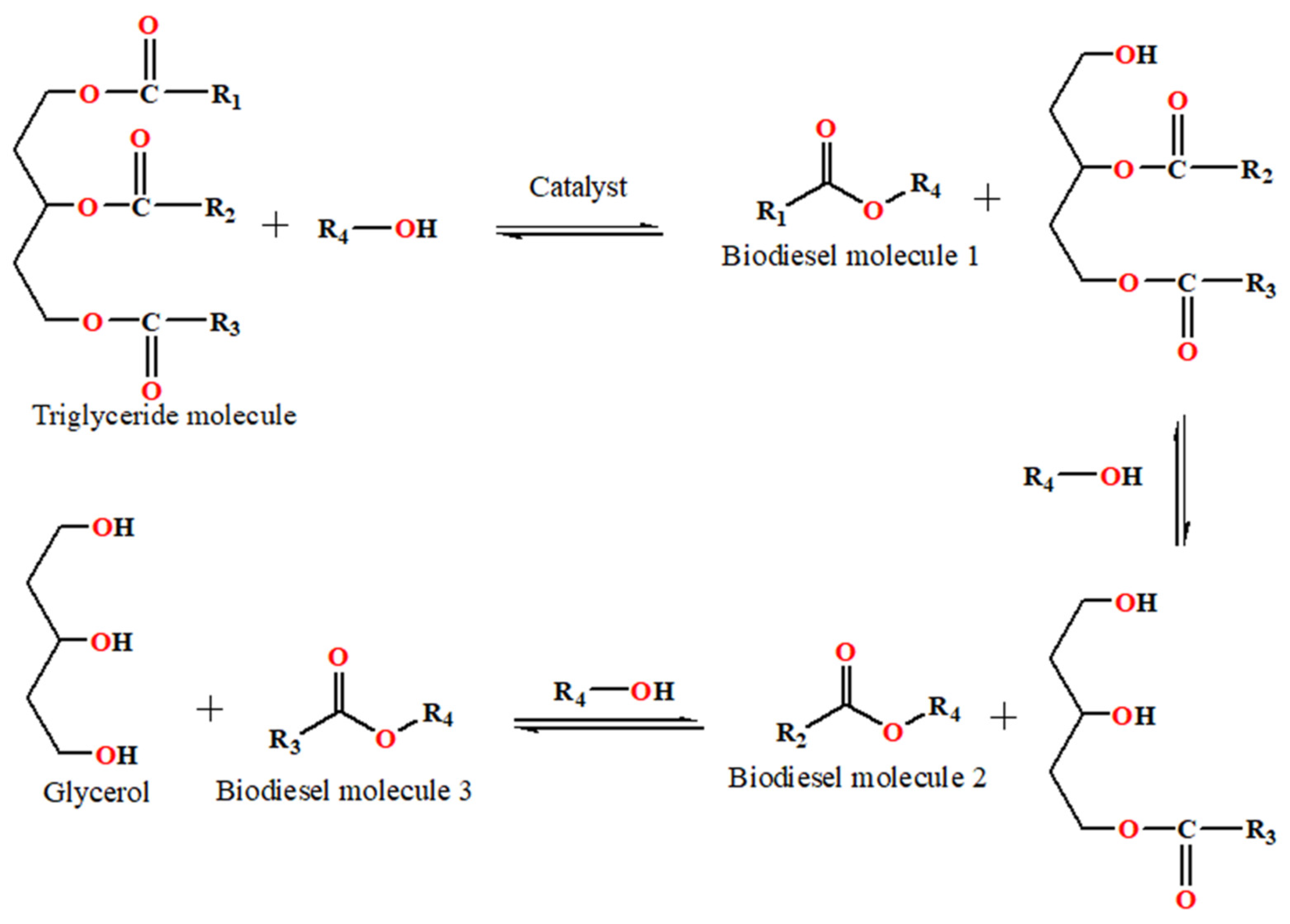

Biodiesel is produced 8-by the transesterification reaction between lipids animal fats or plants and short chain of alcohol methanol or ethanol in a base or acid catalyst. The various process component referred to in the following protocol are clearly. This protocol describes the production of biodiesel from waste vegetable oil via a two-step method.

The demand for biodiesel fuel is going to be very high all over the world. The transesterification of the oil is used to convert the remaining oil completely into biodiesel. Methyl ethyl 2-propyl and butyl esters were prepared from vegetable oils through transesterification using potassium andor sodium.

And CaOFe 2 O 3 27 have been explored for biodiesel production. Biodiesel has emerged as a viable substitute for petroleum diesel. When compared to fossil biodiesel it excels in its bio.

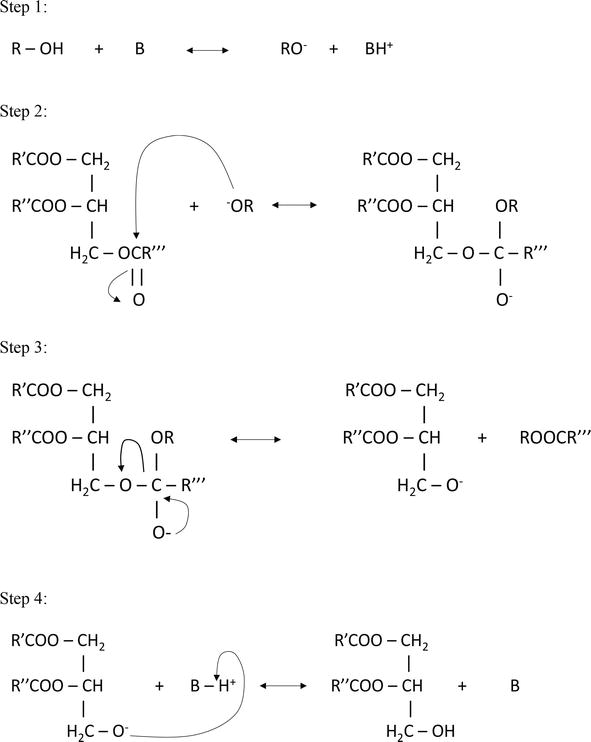

Transesterification process biodiesel is produced from a reaction between vegetable oil alcohol in the presence of base or acid catalyst. Full PDF Package Download Full PDF Package. These two chemical reactions are the core processes in the biodiesel production.

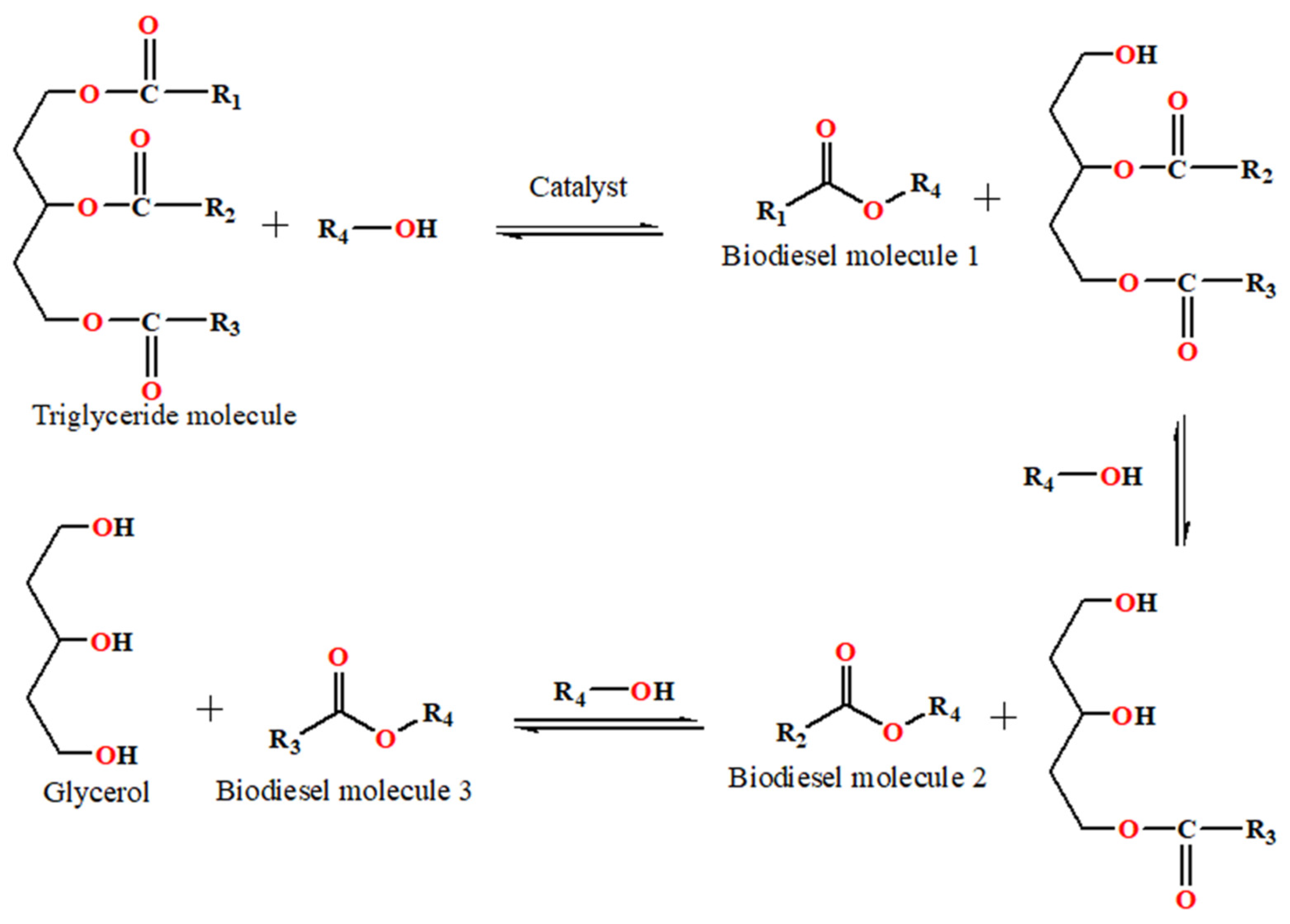

Transesterification implies the conversion of triglycerides TG andor free fatty acids FFAs. And glycerol is used in pellet formation. Via transesterification process in the presence of catalyst.

Heterogeneous CATALIZED TRANSESTERIFICATION PROCESS Both acid and base type homogeneous. Biodiesel is a fuel made from vegetable oils and alcohols Methanol Ethanol ISO-Propanol utilizing a chemical process called Transesterification. Transesterification is the reaction of a fat or oil triglyceride with an alcohol to form.

Properties of biodiesel must be the same complying with the requirements set by international standards. Marine Fresh water Algae. The fuel can be made easily from either virgin or waste vegetable oil.

Reactor Design Culture Trans-esterification. From which we get Biodiesel as product and glycerol as byproduct.

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review Semantic Scholar

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

A Sustainable Protocol For Production Of Biodiesel By Transesterification Of Soybean Oil Using Banana Trunk Ash As A Heterogeneous Catalyst Springerlink

Pdf Transesterification Reaction And Comparative Study Of The Fuel Properties Of Biodiesels Produced From Vegetable Oils A Review

Biodiesel As Renewable Biofuel Produced Via Enzyme Based Catalyzed Transesterification Sciencedirect

Transesterification An Overview Sciencedirect Topics

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

Catalysts Free Full Text Biodiesel Production Using Solid Acid Catalysts Based On Metal Oxides Html

Catalysts Free Full Text Biodiesel Production Using Solid Acid Catalysts Based On Metal Oxides Html

Esterification Transesterification Of Lipidic Wastes For Biodiesel Production Springerlink

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

Pdf Base Transesterification Process For Biodiesel Fuel Production From Spent Frying Oils

Transesterification Srs Biodieselsrs Biodiesel

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Catalysts Free Full Text Nanobiocatalysts For Biodiesel Synthesis Through Transesterification A Review Html

Enzyme Transesterification Process The Resulting Products Of This Download Scientific Diagram